One of the key issues in saving energy and achieving compact designs for small scale mechanical and chemical devices is the manipulation of fluid flow in a controlled manner via surface modifications. Recently, the size of fluidic systems is shrinking from macro to micro size leading to more compact systems. Such emerging microfluidic systems find many applications in many areas such as electronics cooling, chemical reactors, micromixers, biotechnology, drug delivery, micropropulsion, and fuel cells. Due to their extensive use and need, heat and fluid flow in such microfluidic systems attracted attention of many scientists, so that many studies were performed in this promising field.

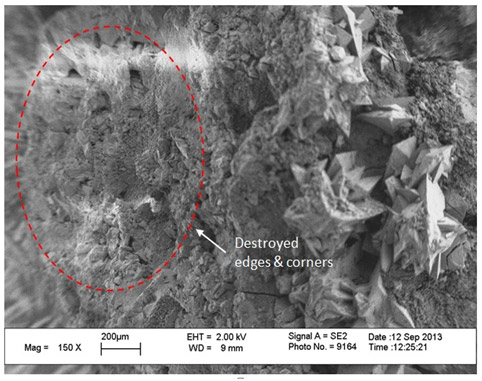

First generation microfluidic systems consisted of plain microchannel configurations. Heat and mass transfer and fluid flow in such plain microchannel systems have been extensively studied in the last decade. Although there remain still many issues with plain microchannels, the state-of-the-art knowledge in the field is such that the heat transfer community is ready to face new challenges. Moreover, there is a strong need for more sophisticated second generation microfluidic systems to have a better performance. The on-going research addresses this lack of information about second generation microfluidic systems having microchannels with modified surfaces. Examples are sensing and detecting disease marker stimulated signals, modification of microchannel surfaces via conformal smart coatings, and integration of related sensors to chip platforms for real time and accurate measurements and flow visualization and processing obtained images. As a result, the research will enable the design and development of futuristic new generation microfluidic systems for Nano Diagnostics.